"Chaitanya” , Established in the year 1996, by Mr. H L RameshKumar, Chairman and MD, explored the manufacturing sector with single minded devotion and singleItem true. The company is engaged in the field of machining and manufacturing of precision components and assemblies for automotive industries. The group has multiple manufacturing locations in Bangalore and all of them are IATF-16949 certified firms.Our main vision is to always give the best to our customers in terms of quality, price and performance and be recognized as a preeminent supplier in the world. We supply more than 25 different components to our customers around the globe, every day, and we promise to live up to their expectation and excel as a reliable supplier in the global market.

Who we are - Established in the year 1996, by Mr. H L RameshKumar, Chairman and Managing Director. Now, we are a leading manufacturer of precision engineering parts, supplying to automotive and non-automotive sector

Employees - Our man power comprises a team of highly experienced engineers, and technicians who are well trained, committed and motivated, totalling to 500 personnel

What we do - With 22 years of experience in precision machining , we have developed and established a wide range of innovative processes for the manufacturing of precision components and assemblies

Growth - We have achieved a steady growth by reinvesting continually into new technologies and modern infrastructure. We have grown from a single manufacturing unit to 5 units, with sales growth from INR.Mio.200 to INR.Mio.1200 , currently

Location - Presently we have manufacturing units in five locations across Bengaluru - Kamaksipalya, Peenya and Rajajinagar.industrial areas

Putting our Customer first

Doing what’s right

Making idea’s Happen

Commitment

Respect & Integrity

We are one of the leading companies in Machining and Manufacturing of Precision components, with operations spanning the automobile & machine building sectors.Looking around our website, you’ll see that our expertise covers the entire machining and manufacturing chain. Research and development towards the machine building and manufacturing is our company’s lifeblood, and we build on that to create, manufacture and support a wide range of products.These extensive capabilities benefit our customers in various ways. Whether we are focusing on the automobile sector working as one of the main suppliers to BOSCH, or working with a local operator or trying on the export market, we focus on customers’ needs and strive to exceed their expectations in quality, delivery, performance and competitive price.Gearing up for the future, we have the key success factors necessary to withstand the winds of change. The encouragement provided to build a highly skilled and creative research and development team, which is reinforced by the state-of-the-art infrastructure. Streamlined and efficient manufacturing capabilities, boosts the technical prowess, high quality production, cost effectiveness and timely delivery. All our companies are certified by IATF-16949.Looking ahead, we are focused on accelerating the execution of our growth strategy while continuing to build on the strength of our brand. The Chaitanya Group is enthusiastic to invest on green energy technology, technological and knowledge based assets.I am incredibly excited about this journey and truly believe the best of the Chaitanya Group in the years to come.

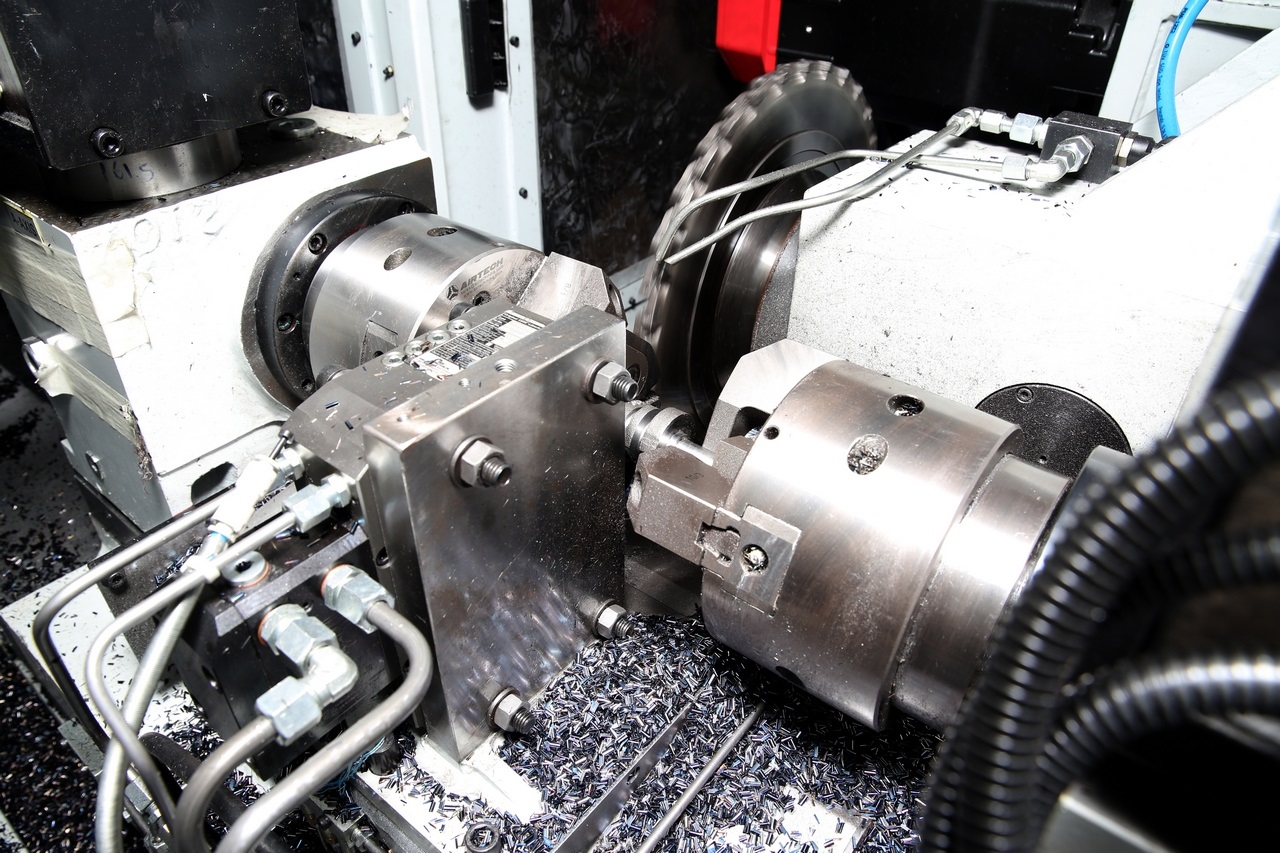

Ready to use parts are precision machined by employing a robust process,using sophisticated machinery.

View More

Soft stage parts are produced using cold-headed pre-parts and machining on CNC machines

Aluminium Die-Casting parts are sourced,precision machined,assembly carried out with in-house components and pressure tested

Facilites

Facilites

World class facility for manufacture and testing of fully finished Camshafts.

Technical Experts

Technical ExpertsTeam of expert engineers for planning, production, QA, Design & Development of special tooling & special gauges.

Technology

TechnologyContinuous Technology Upgradation.

New Product Development

New Product DevelopmentShortest lead time for New Product Development.

Tool Room

Tool RoomWell equipped in-house tool room for manufacture of tooling and gauges

Testing Facilites

Testing FacilitesState of the art, In-house, Fine Measuring Room and Metallurgical laboratory.